05 Apr Wood vs. Plastic

PLASTIC PALLETS vs. WOOD PALLETS

EXPLORING THE PROS AND CONS

Pallets are an essential part of supply chains across almost all industries. When transporting goods on pallets, companies have the choice between two main materials: wood and plastic. While wood pallets have been the go-to-choice for long, plastic pallets have emerged as a popular alternative in recent years. Let’s take a closer look at the main differences between wood pallets and plastic pallets.

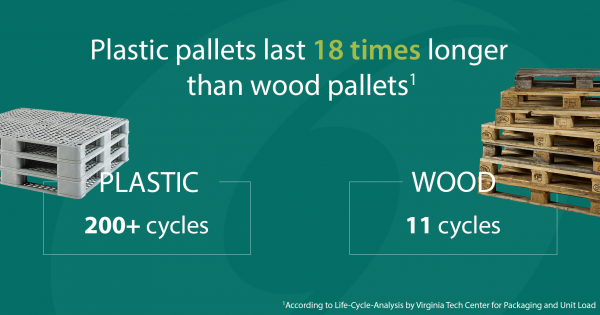

Durability and Lifespan

Wood pallets are typically quite strong, but they are also susceptible to damage and wear and tear. Wood pallets break or crack more easily which results in safety issues for workers handling the pallets. Plastic pallets are generally more durable than wood pallets and less susceptible to damage, splinters or cracks. An ORBIS plastic pallet completed over 200 cycles during Virginia Tech Life-Cycle Analysis testing compared to wood pallets that completed 11 cycles before failure – and we see customers using their plastic pallets even longer. Through the long service life, less resources are needed, and companies save costs in the long run. ORBIS’ newest Odyssey pallet completed even 400 cycles without failure.

Hygiene and Sanitation

With a smooth, closed surface, plastic pallets are generally hygienic and easy to clean. They are designed to interface with manual and automated washing systems. Wood is a porous material that harbors contaminants and is difficult to clean thoroughly at the same time. As wood absorbs water and moisture, the structural integrity of the pallet is affected and now prone to contamination and infestation – all while your product risks exposure. This can pose a risk to the products being transported, particularly in industries where cleanliness is crucial, such as food and beverage.

Environmental Impact

In recent years, there has been a growing focus on reducing the environmental impact of businesses. Plastic pallets are designed to save resources and lessen the negative impact on the environment. Firstly, they are robust and can be used multiple times, therefore reducing the need to produce new pallets. Secondly, they are recyclable at end of life, so they can be repurposed or melted down to make new products. In contrast, wooden pallets are often discarded after single or limited use and end up in landfills. For the positive impact of plastic pallets to kick in, companies need to make sure that they set up their supply chain in a closed loop so that pallets can actually be reused and do not get lost.

Efficiency & Cost-Effectiveness

Although plastic pallets are initially more expensive than wooden pallets, they can be more cost-effective in the long run. As previously mentioned, plastic pallets have a longer lifespan and require less maintenance than wooden pallets, which means that they can be used for a longer period of time. This reduces the need to purchase new pallets, which can ultimately save businesses money. Added to that, plastic pallets are manufactured to consistent specifications and tolerances. They are less likely to vary in size and weight which makes them more efficient for automated handling and storage systems.

When it comes to accelerating your supply chain, you need to move products faster, safer and more cost-effective than ever. Convenience and speed aren’t an expectation – they are a requirement. Any disruptions to the supply chain can be costly, from both a financial and an operational standpoint.

While wooden pallets have been the traditional choice for businesses for many years, plastic pallets have emerged as a popular alternative. The choice between the two will depend on the specific needs of a business. When used in the right application, plastic pallets are more durable, hygienic, resource-efficient, and cost-effective than their wooden counterparts. While the initial cost may be higher, the long-term benefits make them a worthwhile investment for businesses looking to improve their logistics processes.

Are you interested in testing reusable plastic pallets as an alternative to wood pallets in your supply chain? Our packaging consultants are happy to support.

Contact

+49 2233 619 2072