06 Jul Accessories for Pallets

LAYER PADS & TOP FRAMES

FOR FOOD & BEVERAGE PALLETS

HIGHLIGHTS

Compatible with ORBIS F&B pallets

Durable and water-resistant

Unit load stability

Customer identification options available

Customized sizes available

For Maximum Product Protection and Unit Load Stability

Plastic layer pads and top frames allow for efficient and secure stacking of product loads on pallets. As ORBIS products are manufactured from robust plastics, they are reusable and resistant to moisture. Total system solutions consisting of pallets, divider sheets and top frames protect the goods from shifting and reduce the product contamination that can occur from dust, fiber and splinters. Smooth surfaces, rounded corners, chemical resistance and antistatic material further enhance product protection. Top frames and layer pads are, environmentally friendly, 100% recyclable and reduce packaging waste by eliminating fibre sheet disposal.

Designed for Food & Beverage Applications

Our plastic top frames and layer pads are available in different footprints and sizes. In combination with ORBIS plastic pallets, they can easily be integrated into existing systems and supply chains and are designed for the safe and efficient transportation of aluminum and steel cans, plastic and glass bottles and other rigid packaging. For increased cleanliness and workplace safety, our plastic packaging solutions are easy to clean and easy to handle.

Benefits and Added Values of Layer Pads & Top Frames

Quality, service and quick ROI

Lower risk of product damage

Secure stacking of pallet loads

| Typical Sheet Sizes (mm): | |

| 800 x 1200 | 1120 x 1420 |

| 1000 x 1200 | 1180 x 1250 |

| 1120 x 1300 | 1200 x 1350 |

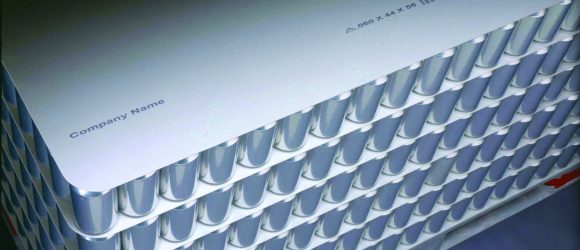

Plastic Layer Pads

Reusable plastic divider sheets are placed between layers of aluminum, steel, glass and plastic cans or bottles used to package food and beverage products. Washable and reusable divider solutions offer increased hygienic properties vs. one-way carton layer pads.

- Available in solid and corrugated styles

- Maximum product protection and load stability for unitized loads

- Non-sloughing, plastic design reduces product contamination

- Reduces packaging waste by eliminating fiber sheet disposal

- Customer name and logo available for direct printing

- Sheet thicknesses range from 0.64 mm to 5 mm

- Customized sizes available

- Reusable, easily cleanable

- 100% recyclable divider sheets

Plastic Top Frames

ORBIS Top Frames are designed to stabilize and protect bulk beverage products such as aluminum and steel cans, glass and plastic bottles, and other rigid packaging. Our plastic top frames are suitable for different applications, where product loads need to be protected and kept clean. The fully enclosed and reversible top frame is easy to clean and operate.

- Product protection from dust and contamination

- Unique lip design available for secure holding of products / stacking of empty frames

- Washable and weather resistant

- 100% recyclable with no metal inserts

- Printable accent strips for customer name and specifications

- Custom colors and custom sizes available

| Typical Frame Sizes (mm): | |

| 800 x 1200 | 1120 x 1420 |

| 1000 x 1200 | 1180 x 1250 |

| 1120 x 1300 | 1200 x 1350 |

Request an individual quote

Your point of contact

If you need additional information on our products

or would like to request a quote,

we are happy to help.

Frequently Asked Questions About Layer Pads and Top Frames

What are plastic layer pads?

ORBIS layer pads are designed to safely and efficiently transport aluminum/steel cans and PET/glass bottles. In order to provide maximum product protection and unit load stability for food and beverage applications, our solid and corrugated layer pads are placed between product loads. Due to the all-plastic design, plastic divider sheets are durable, water-resistant and easy to clean – for a long service life and a quick return on investment.

What are plastic top frames?

ORBIS top frames protect products during storage and transport by unitizing full pallet loads of beverage products (e.g. aluminum and steel cans, glass and plastic bottles). The unique lip design of our top frames enables secure holding of products and stacking of empty frames for space-saving storage opportunities. ORBIS top frames are manufactured from robust plastics without metal inserts and are therefore 100% recyclable. Our offer includes frames with center stringer and with/without lip. We offer multiple customisation options, such as printable logos, custom sizes and colors.

How can layer pads and top frames help increase product protection of pallet loads?

Protecting the goods during storage and transport is the main focus of companies using pallets to move their goods. ORBIS Europe offers layer pads/divider sheets and top frames that are ideal for aluminum and steel cans, plastic and glass bottles and other rigid packaging. Unlike corrugated and solid fiberboard layer pads, the plastic divider sheets are designed for multiple re-use and offer increased cleanliness, strength and moisture resistance. Using an all-plastic design reduces the product contamination that can occur from dust, fiber and splinters. Smooth surfaces, rounded corners, anti-static properties and chemical resistance further enhance product protection.