30 Apr IonPak®

LITHIUM ION BATTERY PACKAGING

IonPak® FOR SOLID DANGEROUS GOODS

HIGHLIGHTS

UN-approved lithium ion battery container

Approval up to 915 kg gross weight

Standard footprints (1200 x 800 / 1200 x 1000 / …)

Customised inner packaging

Consulting by packaging experts

Transporting Lithium-Ion Batteries Safely with the IonPak®

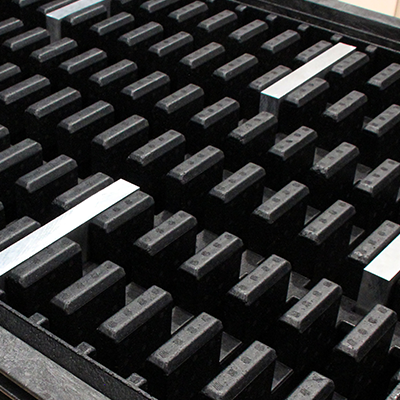

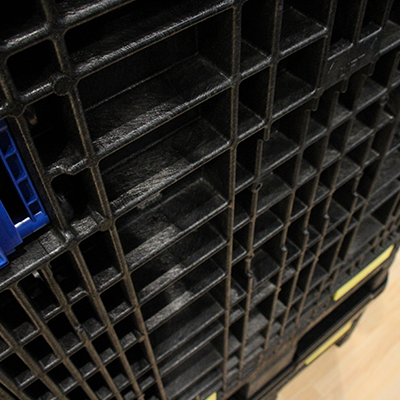

The IonPak® was designed as a reusable FLC for safe transportation of Lithium-Ion Batteries. The lithium battery shipping boxes are suitable for non-certified batteries, prototypes, battery cells, battery modules and batteries in equipment. For increased part protection, the batteries are stored in layers using customised interior packaging solutions that are developed to safely hold dangerous goods. In accordance with the latest dangerous goods guidelines, the shock absorbing interior packaging is adapted to your product. The lithium ion battery packaging utilises standard footprints designed to interface with customers’ existing supply chains. Once batteries are removed at the assembly line, two-unit loads can fit together and packed into one lithium battery container, to reduce return shipping costs.

Lithium-Ion Battery Shipping Boxes: Robust & Sustainable

The ORBIS IonPak® is UN certified to transport solid dangerous goods (e.g. UN3480) and consists of a standard container with customised interior packaging. Due to the special manufacturing process, our lithium battery shipping boxes are extremely robust and durable. We use recycled plastics during manufacturing, leading to CO2 emissions savings. With the collapsible and stackable design, the IonPak battery shipping boxes offer optimised space utilisation and significant cost savings. Speak to one of our packaging experts to learn more about possible applications. A certified dangerous goods safety advisor can inform you about customisation options.

Benefits and Added Value of ORBIS IonPak®

For solid DG & Li-Ion Batteries

Lower risk of product damage

Optimised space utilisation

Possible Styles

The IonPak lithium battery shipping boxes are available in standard and customised sizes. We are happy to advise you.

| Model | HDB1208-960 |

| Outside Dimensions (L x W x H) | 1200 x 800 x 960 |

| Inside Dimensions (L x W x H) | 1120 x 720 x 805 |

| Product Clearance | 776 |

| Collapsed Height | 354 |

| Gross Container Capacity (kg) | 520 |

| Weight (kg) | 65 |

| Model | HDB1210-582 |

| Outside Dimensions (L x W x H) | 1200 x 1000 x 582 |

| Inside Dimensions (L x W x H) | 1113 x 913 x 462 |

| Product Clearance | 434 |

| Collapsed Height | 317 |

| Gross Container Capacity (kg) | 520 |

| Weight (kg) | 51 |

| Model | HDR6548-34 NV |

| Outside Dimensions (L x W x H) | 1638 x 1219 x 879 |

| Inside Dimensions (L x W) | 1557 x 1138 |

| Product Clearance | 681 |

| Collapsed Height | 345 |

| Gross Container Capacity (kg) | 915 |

| Weight (kg) | 98 |

Where to use the IonPak®

Our lithium ion battery packaging is suitable for different industries.

Automotive Lithium Ion Battery Packaging

The ORBIS IonPak is certified to transport solid dangerous goods. That includes lithium-ion batteries, airbags, belt tensioners and other automotive components that need certified packaging solutions for storage and transport. ORBIS lithium ion battery packaging offers enhanced product protection, improved flow of material and significant cost savings.

Industrial Lithium Battery Shipping Boxes

The ORBIS IonPak is suitable to transport lithium-ion batteries safely. The UN approved packaging is certified for solid dangerous goods in a variety of different industries. With a robust outer packaging, customised interior packaging and dust cover, our lithium battery shipping boxes optimise product flow in industrial supply chains. Our packaging experts can advise you.

Request an individual quote

Your point of contact

If you need additional information on our products

or would like to request a quote,

we are happy to help.

ORBIS Lithium-Ion Battery Packaging in Detail

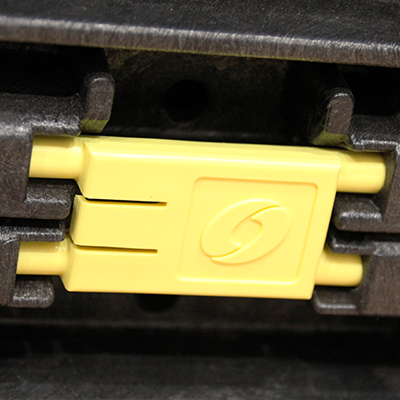

Only three different kinds of spare parts for easy and quick maintenance on site – without special tooling

UN Certified Lithium Battery Shipping Boxes

Frequently Asked Questions About Lithium Battery Shipping Boxes

Why are lithium-ion batteries classified as dangerous goods?

Due to their high energy density, lithium-ion batteries are one of the most used battery types – not only in the automotive industry. Li-ion batteries should only be handled and packaged by trained staff as improper use can represent a safety hazard. Lithium-ion batteries react to many different substances. When handled, stored or transported improperly, the batteries can overheat, catch fire or even explode. That is why all batteries and cells containing lithium are classified as Class 9 Dangerous Goods and the transportation of Lithium-ion Batteries is subject to strict regulations. Lithium Battery Shipping Boxes such as the IonPak are developed to transport these goods and fulfill all the requirements to safely transport lithium-ion batteries.

How do you safely transport Lithium-Ion Batteries?

According to hazardous goods law, the transportation of lithium-ion batteries is subject to strict regulations. So not every packaging is suitable to store and transport lithium-ion batteries. UN certified containers for transporting and storing lithium batteries are needed to comply with the regulations. ORBIS’ lithium battery shipping boxes fully hold and protect the batteries from damage or shocks of any kind. That includes isolating loose cables and poles. In order to prevent batteries from shifting, ORBIS uses customised protective and shock-absorbing dunnage layers in its UN packaging. The interior packaging can neither be conductive, nor inflammable. The outer packaging is tested in a drop test for its robustness and shock-resistance. Over the course of its life cycle, a battery goes through the following phases: prototype, battery cell, battery module, battery pack. The ORBIS IonPak lithium battery container is suitable to transport non-certified batteries, prototypes, battery modules as well as batteries in equipment.

What is a UN certification for packaging?

Packaging solutions for dangerous goods have to be certified according to UN standards. UN mark is an international system created by the United Nations, which is used for the classification, packaging, marking and labeling of dangerous goods, in order to transport them safely (by road, rail, sea and air). Independent institutions carry out the necessary tests to issue a UN certification mark. The UN packaging must meet or exceed minimum standards of performance before it can be used. An expert committee of the UN regularly list all dangerous substances and goods and assigns each a so-called UN number. Associated with each UN number is a hazard identifier, which encodes the general hazard class and subdivision. ORBIS Europe offers UN approved dangerous goods packaging in different footprints. Our dangerous goods boxes are certified for solid dangerous goods (e.g. UN3480 – Lithium-Ion Batteries). The certifications UN4H2/Y and UN50H/Y of the lithium ion battery packaging apply for recycled and primary materials.