09 Jul HDB1210

PLASTIC BULK CONTAINERS

HDB1210 1200 x 1000

HIGHLIGHTS

900 kg weight capacity

Stackable 1 + 5 static / 1 + 2 dynamic

Return ratio 1 : 3

Available with 3 Runners or Full Stringer

Plastic Bulk Containers in Four Different Heights

ORBIS offers reusable bulk containers and collapsible industrial containers for every need. The HDB1210 containers are designed to protect and transport parts in global automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are robust and offer a long service life – leading to an attractive ROI and a lower total cost of ownership. Our reusable bulk containers are 100% recyclable with a buyback option at the end of the service life: We offer to buy back obsolete plastic containers and reprocess them into new packaging products. Key features of the HDB1210 include multiple heights, access door and bottom configurations as well as enhanced maintenance features for easy, on-site repair and part replacement.

Optimised space utilisation with collapsible bulk containers

The 1200 x 1000 plastic bulk containers are part of line BulkPak® line and available in multiple heights for efficient space utilisation. The ORBIS HDB1210 collapsible containers offer a return ratio of 1 : 3 and reduce the shipping of air during return transport to a minimum. When stored, the bulk storage containers help save valuable floor space as they can be stacked up to 6 bins high. Due to the stackable and foldable design, companies realise significant cost savings across the entire supply chain.

Benefits and Added Value of ORBIS Bulk Containers

Stackable 1 + 5 static / 1 + 2 dynamic

Decreased product damage, no rust

Improved workplace safety

Product Specifications

| Model | HDB1210-600 STR | HDB1210-582 R |

| Bottom Configuration | Full Stringer | 3 Runners |

| Outside Dimensions (L x W x H) | 1200 x 1000 x 600 | 1200 x 1000 x 582 |

| Inside Dimensions (L x W x H) | 1113 x 913 x 462 | 1113 x 913 x 462 |

| Product Clearance | 434 | 434 |

| Collapsed Height | 335 | 317 |

| Container Capacity (kg) | 900 | 900 |

| Weight (kg) | 54 | 51 |

| Model | HDB1210-888 STR | HDB1210-870 R |

| Bottom Configuration | Full Stringer | 3 Runners |

| Outside Dimensions (L x W x H) | 1200 x 1000 x 888 | 1200 x 1000 x 870 |

| Inside Dimensions (L x W x H) | 1113 x 913 x 750 | 1113 x 913 x 750 |

| Product Clearance | 723 | 723 |

| Collapsed Height | 335 | 317 |

| Container Capacity (kg) | 900 | 900 |

| Weight (kg) | 68 | 64 |

| Model | HDB1210-750 STR | HDB1210-732 R |

| Bottom Configuration | Full Stringer | 3 Runners |

| Outside Dimensions (L x W x H) | 1200 x 1000 x 750 | 1200 x 1000 x 732 |

| Inside Dimensions (L x W x H) | 1113 x 913 x 612 | 1113 x 913 x 612 |

| Product Clearance | 585 | 585 |

| Collapsed Height | 335 | 317 |

| Container Capacity (kg) | 900 | 900 |

| Weight (kg) | 61 | 57 |

| Model | HDB1210-998 STR | HDB1210-980 R |

| Bottom Configuration | Full Stringer | 3 Runners |

| Outside Dimensions (L x W x H) | 1200 x 1000 x 998 | 1200 x 1000 x 980 |

| Inside Dimensions (L x W x H) | 1113 x 913 x 860 | 1113 x 913 x 860 |

| Product Clearance | 834 | 834 |

| Collapsed Height | 335 | 317 |

| Container Capacity (kg) | 900 | 900 |

| Weight (kg) | 73 | 69 |

Areas of Application

Our Bulk Plastic Containers are suitable for:

Automotive Industry

ORBIS plastic bulk containers are an efficient alternative to conventional packaging, such as steel boxes and wooden crates in automotive applications. For OEMs and suppliers, efficiency and sustainability in the supply chain is a growing focus: With our durable, returnable plastic containers, you can optimise capacity and space utilisation and reduce CO2 emissions.

Industrial Manufacturing

ORBIS Europe offers collapsible industrial containers that maximize product flow efficiency in the industrial manufacturing environment. The ORBIS HDB1210 is a sustainable and efficient alternative to conventional industrial packaging. The plastic bulk container offers a weight capacity of 900 kg and holds heavy parts and components of manufacturing companies.

ORBIS HDB1210 in Detail

Only three different kinds of spare parts for easy and quick maintenance on site – without special tooling

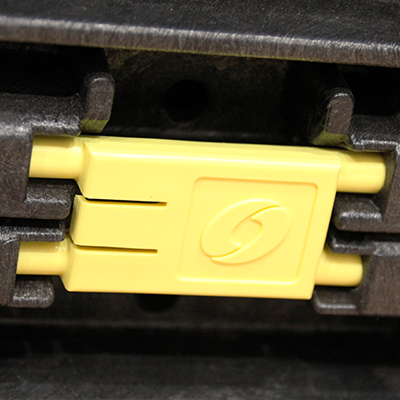

Latches for side walls and doors

Access doors with hinges

Connectors for exchangeable side walls

Special wall design for increased stability

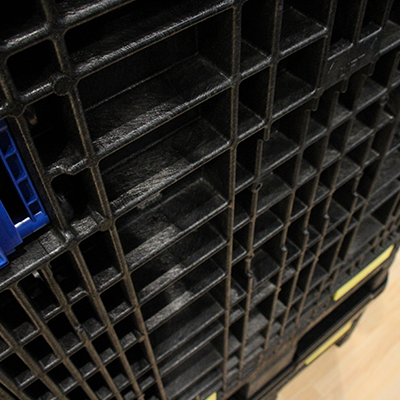

Full Stinger Version

3 Runner Version

Other Large Plastic Containers

Request an individual quote

Your point of contact

If you need additional information on our products

or would like to request a quote,

we are happy to help.

Frequently Asked Questions About Plastic Pallet Containers

What are the benefits of plastic bulk containers?

Reusable plastic bulk containers can be used to transport and store larger parts and components of all kinds. Plastic containers have a lower tare weight than equivalent steel boxes but offer the same stability and weight capacity. ORBIS’ reusable bulk containers are collapsible for space and cost savings: They combine stability and longevity with increased sustainability and supply chain efficiency. The 1200 x 1000 industrial size containers can be reused multiple times before being recycled at the end of their service life. They fulfill the requirements of different industries and companies and can be used flexibly in manufacturing industries, such as the automotive industry.

How can I adapt the HDB1210 to fit my supply chain needs?

ORBIS bulk plastic containers are available in a variety of different footprints and variants. The large containers are compatible with European and American standard footprints and can be integrated into existing supply chains. You can choose from different bottom and access door configurations (0-4), inner packaging solutions and other options to adapt the HDB1210 to your packaging needs. The HDB1210 containers with covers ensure comprehensive product protection. Our portfolio of FLCs is also available with customer-specific dimensions. We are manufacturer of plastic bulk containers and support you with the development and production of a wholly new, project-specific load carrier. One of our packaging experts can advise you.

What happens when a bulk container is damaged?

Due to special manufacturing processes, ORBIS bulk containers are extremely durable and robust when handled properly. In the rare case of a damaged container, you can easily replace the damaged parts with original ones. Just a few steps are required to disassemble separate parts, such as side walls, latches, hinges or the base, and replace them with new ones. No special tooling is necessary to perform these steps. For additional information, see our handling and repair videos.