30 Oct Transporting batteries safely from A to B: Plastic dangerous goods containers make it possible

MASTERING THE BATTERY TRANSITION WITH SUSTAINABLE REUSABLE PACKAGING

Transporting batteries safely from A to B: Plastic dangerous goods containers make it possible

When transporting dangerous goods – and therefore also lithium-ion batteries – companies face particular challenges. They have to comply with strict safety regulations and high protection requirements in order to transport sensitive products safely. At the same time, companies are increasingly calling for sustainability. Reusable plastic packaging combines safety with environmental friendliness.

Requirements for the packaging solution:

- As lithium-ion batteries are classified as Class 9 dangerous goods according to RID / ADR / IMDG / IATA-DGR, the transport packaging must fulfill strict legal requirements.

- Companies demand UN-certified, individual, automation-friendly, and sustainable packaging at a reasonable cost.

- During transportation batteries from external influences such as impact, to prevent a thermal runaway in the worst case.

- In addition, a further supply chain is created for used batteries in the return to the recycler or for use in energy storage systems – with even higher requirements for transport packaging.

“The task of the packaging industry is to protect the product from the environment and the environment from the product. It is therefore crucial to incorporate the packaging solution into the design of the supply chain as early as possible.“

Christian Hemming, Technical Director EMEA at ORBIS Europe

From ORBIS: the IonPak® dangerous goods container:

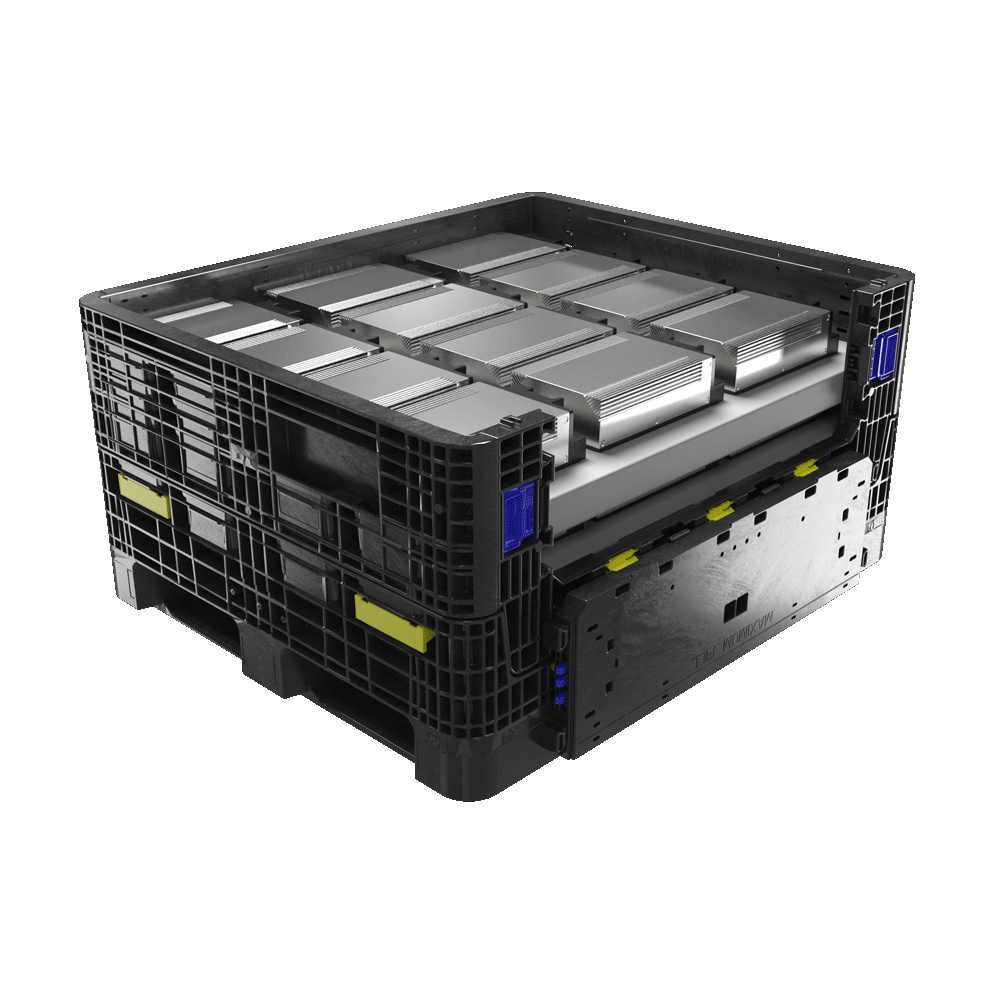

With the IonPak® dangerous goods container, ORBIS has developed a smart alternative to conventional packaging made of corrugated cardboard, steel or wood.

In the right application, it is the ideal solution for transporting lithium-ion batteries safely and sustainably. The IonPak® is used in particular for production-ready battery cells or modules, smaller battery packs, and the return of batteries at the end of their service life.

Hitting three birds with one stone – the reusable load carrier at a glance:

- Safety: The IonPak® is approved for the transportation of solid dangerous goods (packaging group II) following RID / ADR and is UN-certified (UN4H2 / UN50H). Depending on the version, the gross payload is 477 to 915 kg. It consists of a robust large load carrier with standard European dimensions (1200 x 800 / 1200 x 1000 / 1600 x 1200 mm) and hazardous goods-optimized inner packaging that can be adapted to individual customer requirements. The foam trays inside the packaging ensure impact resistance and protect the battery cells from high-temperature fluctuations and contamination.

- Cost-effectiveness: The foldable and stackable design allows companies to optimize their transport capacity and save costs. In addition, the solution can be easily integrated into existing and automated processes. The initially higher purchase costs compared to disposable solutions are compensated for by the long service life.

- Sustainability: As battery production generates considerable amounts of emissions, processes and supply chains must be designed to be as sustainable as possible. The IonPak® consists of a high proportion of recycled material, with a raw material recycling rate of 100%. The solution is reusable, survives many cycles in the supply chain and is bought back at the end of its service life, recycled and processed into new products.

“Disposable dangerous goods packaging is still largely used for the transportation of batteries and other dangerous goods and is disposed of after a single use. This must change. Waste avoidance comes before waste recycling.“

Christian Hemming, Technical Director EMEA at ORBIS Europe

Would you like to delve deeper into the topic? You can find even more information in the ORBIS white paper ”The challenge of transporting dangerous goods: transporting batteries in reusable packaging safely and sustainably”. Click here to download.

Contact

+49 2233 619 2072