27 Jan Beverage industry: reusable makes the difference

Wood is a thing of the past – plastic pallets as an ecological and economical alternative

Beverage industry: reusable makes the difference

Wood is a thing of the past – plastic pallets as an ecological and economical alternative

8 a.m. in the beverage production of a medium-sized company. The first trucks roll in, the employees unload the pallets – and yet another wooden pallet is damaged. Splinters and nails endanger the safety of employees and the pile of unusable pallets grows in the warehouse. This scenario is partly part of everyday life in companies in the beverage industry. But there is another way: A rethink towards plastic solutions changes logistics and creates added value – for companies, the environment and employees.

Climate targets, hygiene, customer expectations: this is what the industry is concerned about

The beverage industry is currently facing a wide range of challenges: In addition to a smooth flow of products, supply chains must also meet strict industry-specific requirements. Ensuring hygiene standards is just as crucial as protecting products during transport. A key set of rules in the industry is the HACCP concept (“Hazard Analysis Critical Control Point”). It stipulates that the food industry – and therefore also the beverage industry – must use logistical aids to ensure the safety of the goods being transported. At the same time, the industry is exposed to growing customer expectations and increasing political requirements: The German government’s current Climate Protection Act plans to reduce CO2 emissions by 55 percent by 2030 compared to 1990. Companies must rethink and adapt their processes and supply chains accordingly.

This is exactly where transport packaging solutions come into play – they are an important key in this area of tension between sustainability, efficiency and hygiene. Jürgen Krahé, Senior Commercial Director EMEA, sums it up: “The requirements for transport packaging in the beverage industry are extremely high . Anyone who wants to meet these needs needs innovative, durable and sustainable solutions. Plastic packaging offers exactly that.”

Sustainable logistics: why plastic is the better choice

Wooden pallets still dominate in many warehouses. But given the increasing focus on circular economy and resource conservation, as well as the problems described in the introductory scenario, plastic pallets are increasingly becoming an alternative in various industries. Why is that? We’ll explain

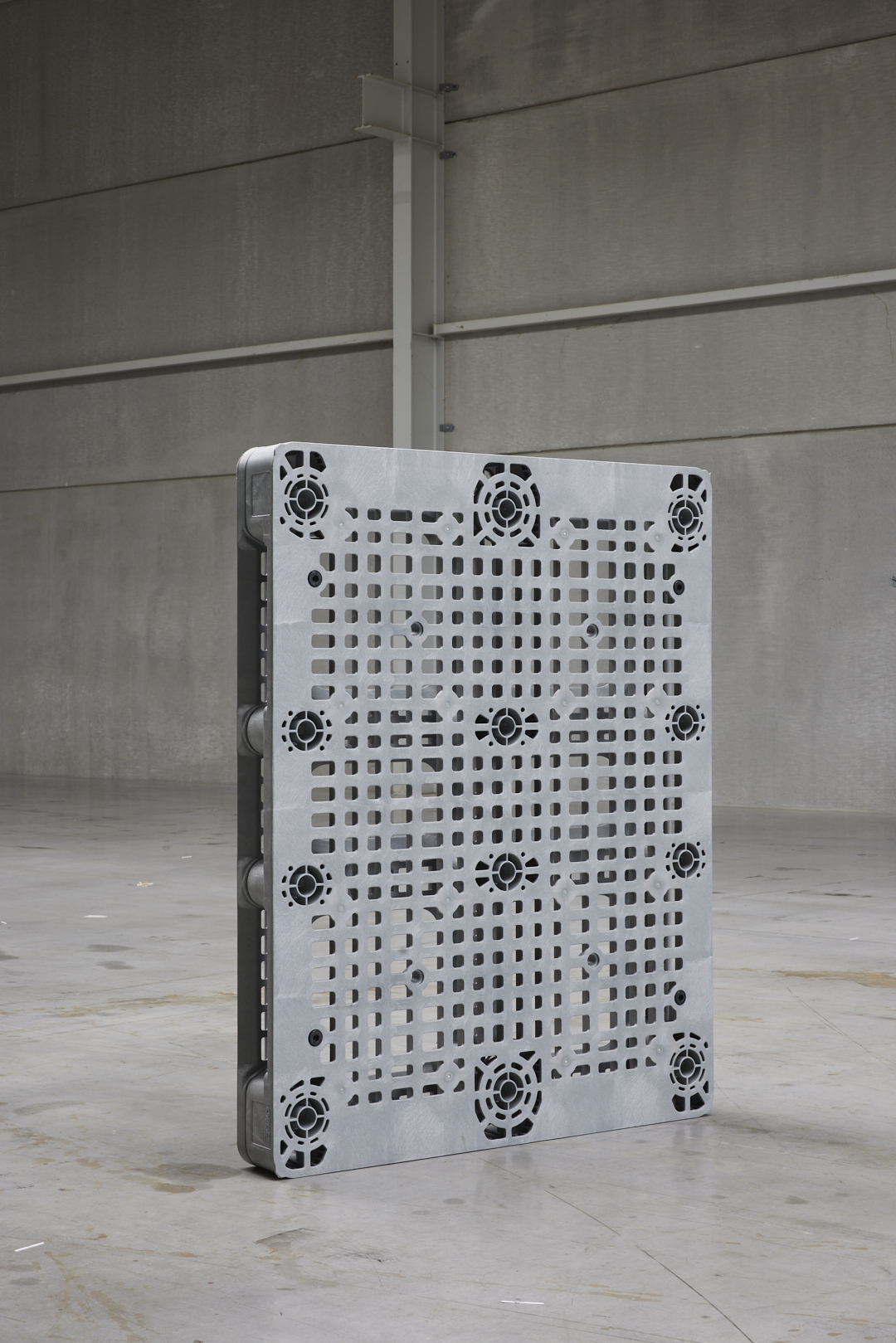

Hygiene: Plastic pallets are easy to clean thanks to their closed, smooth surface. Due to the ventilation holes in the pallet deck, they are also suitable for automated washing and drying systems.

- Longevity: In a life cycle analysis by the Center for Packaging and Unit Load Design (CPULD) at Virginia Polytechnic Institute and State University, a plastic pallet managed 200 cycles without damage. That’s over 1,800 percent more than a wooden pallet, which managed just eleven cycles under the same conditions. The longer companies use packaging, the fewer resources they use.

- Sustainability: Used plastic pallets can be recycled and processed into new products.

- Efficiency: Due to their dimensional stability, the pallets are ideal for automated processes.

- Safety: Since plastic has no splinters or sharp edges, the risk of injury to employees is reduced.

Conserve resources: reuse instead of disposing

ORBIS Europe buys back used, irreparable or obsolete containers at the cost of the material and returns them to the production process – this benefits the environment and companies:

- By using secondary raw materials instead of primary materials, the CO2 balance is reduced . Companies are thus making a contribution to the EU climate goals.

- Due to the closed raw material cycle, no materials enter the waste stream.

- At the same time, companies save costs: They do not pay for the disposal of solid waste and also generate cost advantages when purchasing new equipment.

Reusable creates added value

Like many other industries, the beverage industry is facing a paradigm shift. Plastic transport packaging can support this change. It combines hygiene, durability and sustainability – exactly what modern supply chains need.

Are you interested in further information or would you like to find out more about our pallets for the beverage industry? Then click here .

Contact

+49 2233 619 2072

Hygiene: Plastic pallets are easy to clean thanks to their closed, smooth surface. Due to the ventilation holes in the pallet deck, they are also suitable for automated washing and drying systems.

Hygiene: Plastic pallets are easy to clean thanks to their closed, smooth surface. Due to the ventilation holes in the pallet deck, they are also suitable for automated washing and drying systems.